Tucker Engineering, Inc. Provides Design & Manufacturing Services for Thermal Solutions

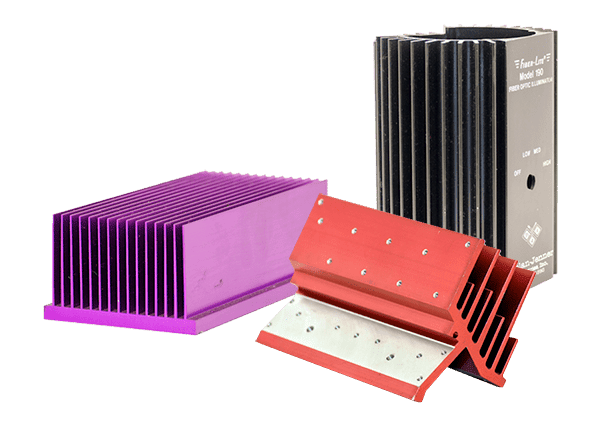

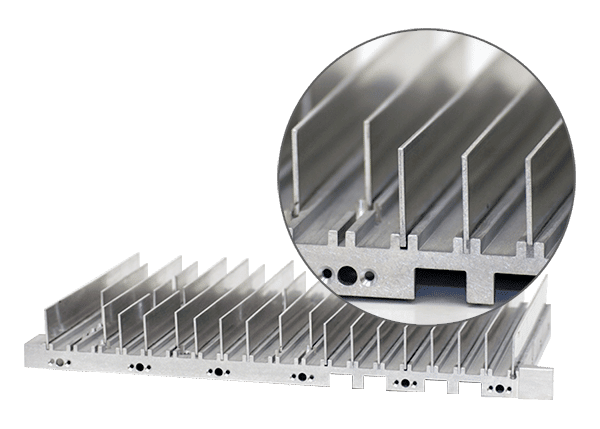

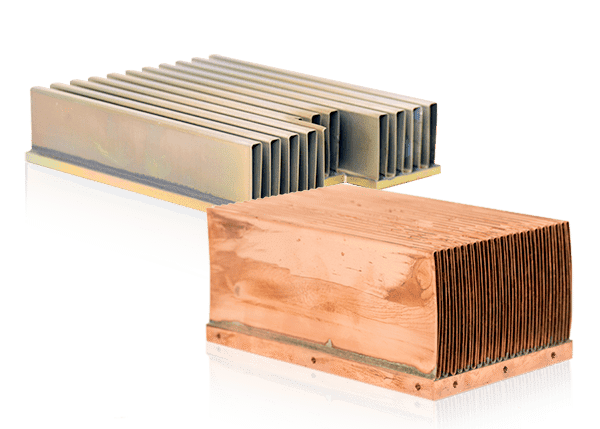

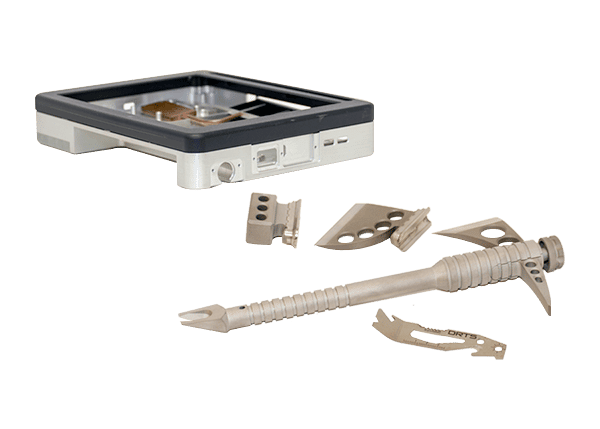

Tucker Engineering Inc (TEI) is a custom job shop located in Peabody Massachusetts. Tucker Engineering has the capability of producing parts from prototype through production, in our state of the art CNC machine shop. We can offer a wide range of services from, precision cutting, 3 & 4 axis milling, CNC turning, deburring, to assembly and finishing.

To assure quality and satisfaction for our customers, our inspection department monitors work flow from 1st piece to final inspection. Tucker Engineering will also aid customers in CAD/CAM design and engineering. From standard shapes to custom extrusions, we do it all.

Industries Include:

- Military

- Medical

- Automotive

- Power supply

- Electronics

- Transportation

- Architectural

- Aviation

- Lighting

- Microwave

- Computer

- Semi Conductor